PUMPING SOLUTIONS

Degassers

OVERVIEW

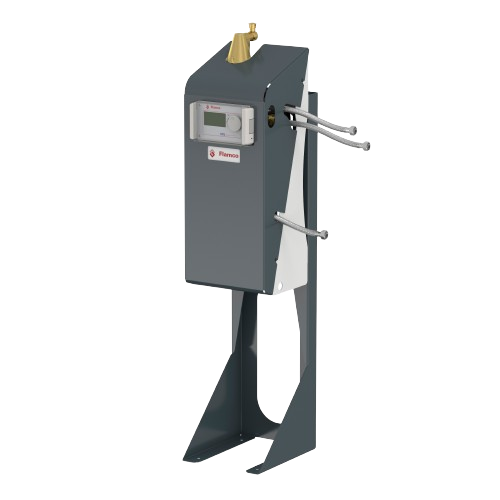

Degassers are critical devices that remove unwanted gases and ensure that the air quality remains at a high standard. Vacuum degassers are typically used in industrial applications where unwanted gases can harm processes and the final product. Food, pharmaceutical, oil, and gas industries are the most at risk, making degassers a must-have for their operations.

If you have any questions, feel free to call us or use our quote form

To speak to one of our agents online, click here

How do Degassers Work?

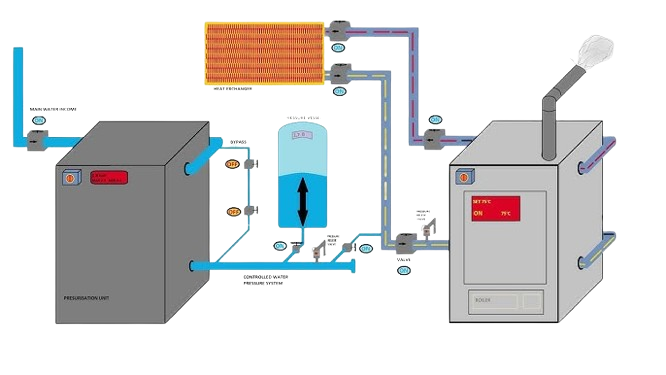

Degassers or vacuum degassers function on a simple yet highly effective principle. They create a vacuum within a chamber, causing the liquid to boil at a lower temperature. As the liquid boils, the gases and air bubbles trapped within it are released and collected, leaving behind a degassed liquid. This process is beneficial in applications where the presence of gas can affect the final product’s quality.

A vacuum degasser increases the efficiency of today’s advanced heating and cooling systems. They use a pump and vacuum chamber to remove dangerous gases from the system. Advanced degassers effectively remove all lingering gases, including hydrogen sulphide and corrosive oxygen.

It is recommended to use a magnetic filter with your degasser to remove any dirt simultaneously as the gases are removed, leaving your system clean.

Key Features

- Vacuum pump capacity

- Degassing chamber size

- Material

Benefits of Degassers

- Removes all gases, including dissolved gases, free air and microbubbles

- Absorptive fluid ensures the removal of trapped gases

- Energy-efficient technology

- Consistent product quality

- Suited for a range of industrial applications

- Combats corrosion of water systems/ pipework

Types of Degassers

There are two primary types of degassers – batch and continuous degassers. Batch degassers are used for smaller liquid volumes, while continuous degassers are employed in high-volume production processes. The choice between the two depends on the industry’s specific requirements and the production scale.

Main Industries:

- Food

- Pharmaceutical

- Oil & Gas

Batch Degassers

Batch degassers, as the name suggests, operate batch-wise. They process a fixed volume of liquid at a time, subjecting it to vacuum conditions to remove dissolved gases. The liquid is typically placed in a chamber, then sealed and evacuated to create a vacuum environment.

The reduction in pressure causes dissolved gases to escape from the liquid, which is then collected or released. Once the degassing process is complete, the chamber is opened, and the degassed liquid is removed, ready for further processing or use.

Continuous Degassers

Continuous degassers, unlike batch degassers, operate continuously, allowing for a steady flow of liquid through the degassing system.

In a continuous degasser, the liquid flows through a degassing chamber or unit exposed to vacuum conditions. As the liquid flows, gases are continuously removed, ensuring a constant degassing process. The degassed liquid exits the system, ready for further processing or use.

Applications of Degassers

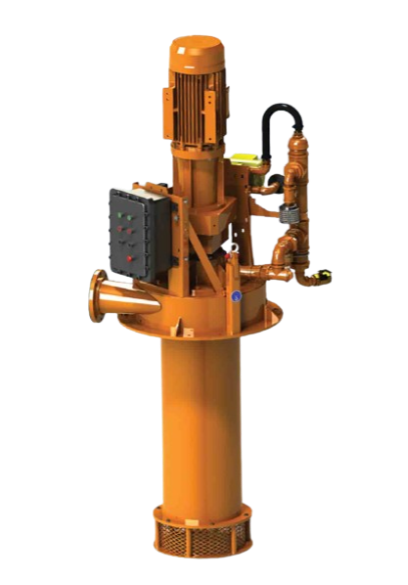

There are different applications that degassers can be used for. In the oil and gas industry, they are crucial for removing gas from drilling fluids and ensuring safe and efficient drilling operations. A centrifugal force degassing unit is typically necessary for this heavy-duty operation. The centrifugal force degasser acts on the mud and increases the force acting on the gas bubbles, and as the gas bubbles rise towards the surface, they escape the mud and are broken down further.

In the food industry, these machines are used to deaerate liquid products like sauces, soups, and beverages. The key benefits of using a degasser in the food industry are enhanced product quality, extended shelf life and reduced spoilage. The pharmaceutical industry relies on vacuum degassers to ensure the purity and quality of pharmaceutical products. Pharmaceutical products must be pure and free of contaminants. Vacuum degassers are critical in ensuring that pharmaceutical liquids meet quality standards.

What to consider when choosing the right degasser:

- Industry & Application

- Manufacturer

- Liquid volume

- Specific site requirements

Maintenance and Care of Degassers

Regular maintenance is vital to extending the lifespan of vacuum degassers. This includes cleaning and inspecting seals and ensuring all components function correctly. Manufacturers provide maintenance guidelines.

Vacuum degassers are indispensable tools in various industries, ensuring the quality, purity, and safety of liquid products. By removing unwanted gases and air bubbles, they contribute to the production of superior-quality goods. There will be more efficient and innovative degassing solutions as technology advances in the coming years. Get in touch with our expert team for a quote on our wide range of degassers or further technical information.

Packaged Pumping Sets

Designed to deliver sufficient volume and water pressure

Fire Pumps

Full range of Fire Protection Pumps from small to packaged systems

Packaged Pumping Stations

Pumping stations offer the ideal solution where gravity drainage is not possible

RECENT PROJECTS

Recent Projects Completed

Tricel is one of the largest UK pump distributors specialising in Commercial Building Services projects. We offer a wide range of products from circulator pumps to Wet Riser booster sets.

Our team includes experts which are happy to select and quote your equipment requirements, or attend site and size the equipment from scratch. We at Tricel pride ourselves on the highest possible levels of customer service, before, during, and after project completion.

We provide preventative maintenance contracts and also cater for specific repairs, including replacements seals, or complete overhauls.

150

Hotels

125

Schools

50

Hospitals

300

Apartment Blocks

305

Commercial Buildings

Pump Commissioning

Our skilled team of specialist engineers are ready to specify, supply, install, service and maintain pumps and their control systems

Service & Maintenance

We provide preventative maintenance contracts and also cater for specific repairs, including replacements seals or complete overhauls

SITE SURVEYS & ASSESSMENTS

Our technical team will visit your location and complete an entire site survey to ensure your project is accurately specified, and the most suitable system installed and maintained to the highest quality

Customer Technical Support

Through our 35 years of operation, we have accumulated a wealth of product knowledge and application experience that we use to support our customers