PUMPING SOLUTIONS

Positive Displacement Pumps

OVERVIEW

As a leading pump distributor in the UK specialising in commercial building services and industrial applications, we provide a vast range of products, including positive displacement pumps. Our expert team can also perform specific repairs, including seal replacements and overhauls!

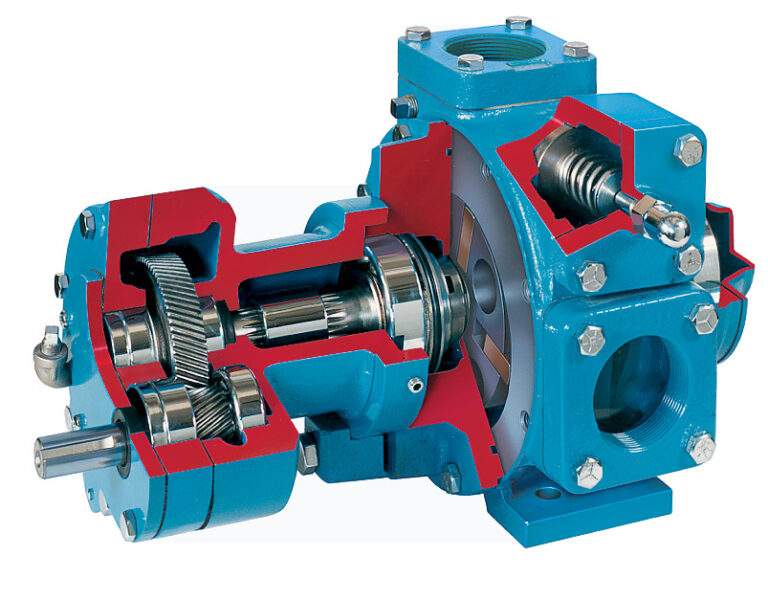

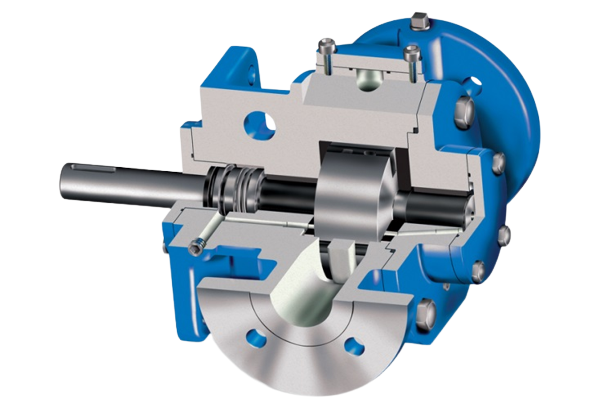

Positive displacement pumps are an alternative to centrifugal pumps and are widely referred to as reciprocating or piston pumps. A positive displacement pump does not use an impeller. Instead, it uses rotating or reciprocating parts to shift liquid.

If you have any questions, feel free to call us or use our quote form

To speak to one of our agents online, click here

Different types of positive displacement pumps

Positive displacement pumps are essential in various industries, playing a crucial role in fluid transfer applications. There are different types of positive displacement pumps, and Tricel supplies a wide range manufactured by the most renowned brands.

- Reciprocating Pumps: reciprocating pumps utilise a piston, plunger, or diaphragm to generate a reciprocating motion. This motion creates a pressure differential, causing the fluid to move. One of the most common examples is the reciprocating piston pump. Prominent manufacturers in this category include Ingersoll Rand and Grundfos.

- Rotary Pumps: these pumps operate by rotating elements, such as gears, lobes, or screws, to move the fluid. Gear pumps, for instance, are widely used in hydraulic systems. Viking Pump and Blackmer are reputable brands known for their high-quality rotary pumps.

- Diaphragm Pumps: these pumps use a flexible diaphragm to move fluid through a series of cycles. This type is especially suitable for applications requiring precise control and minimal leakage. AOD (Air-Operated Diaphragm) pumps are a popular subcategory with low to moderate capacity, pressure, low efficiencies, no seal and high pulsation.

- Peristaltic pumps: these pumps are also referred to as hose pumps, peristaltic pumps employ rollers to compress and decompress a flexible tube, creating a peristaltic motion that propels the fluid. This design offers benefits such as gentle pumping and ease of maintenance.

- Screw Pumps: they use rotating screws to move fluids along the screw axis. This type is known for its ability to handle viscous fluids effectively.

- Progressive Cavity Pumps: they have a rotor rotating within a housing called a stator. The rotor is always metallic, and the stator is made of a rubber material. Progressive Cavity Pumps, also known as eccentric screw pumps, operate through the rotation of the metallic rotor creating a progressing cavity that moves fluid.

Advantages of positive displacement pumps

- Ability to handle varying levels of viscosity

- High efficiency

- Precise volume measures (Dosing Pumps are a popular type of positive displacement pumps used for accurate chemical dosing)

- High-pressure generation

- Creates suction to pump water from a lower level

Centrifugal Pumps vs Positive Displacement Pumps

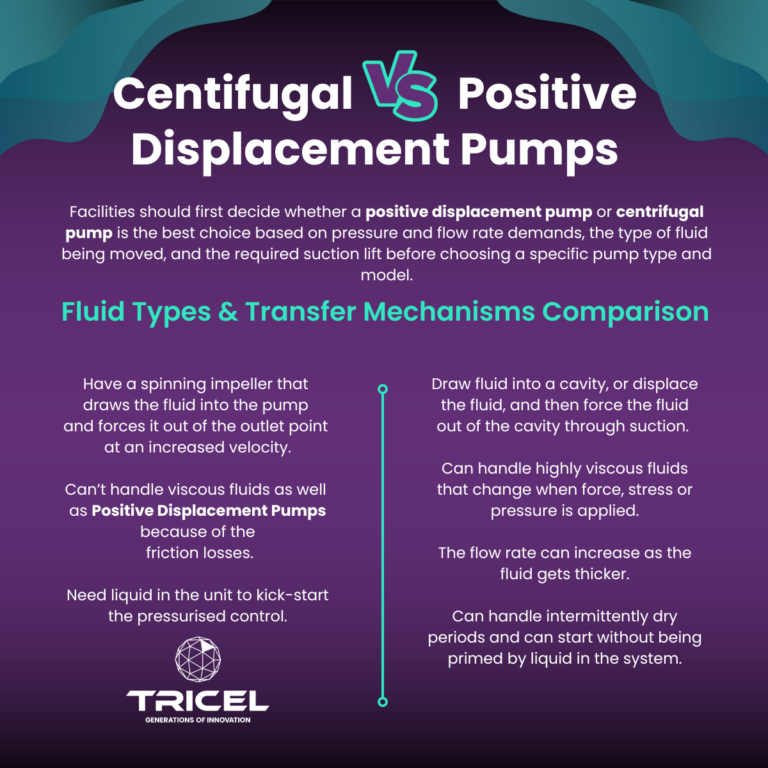

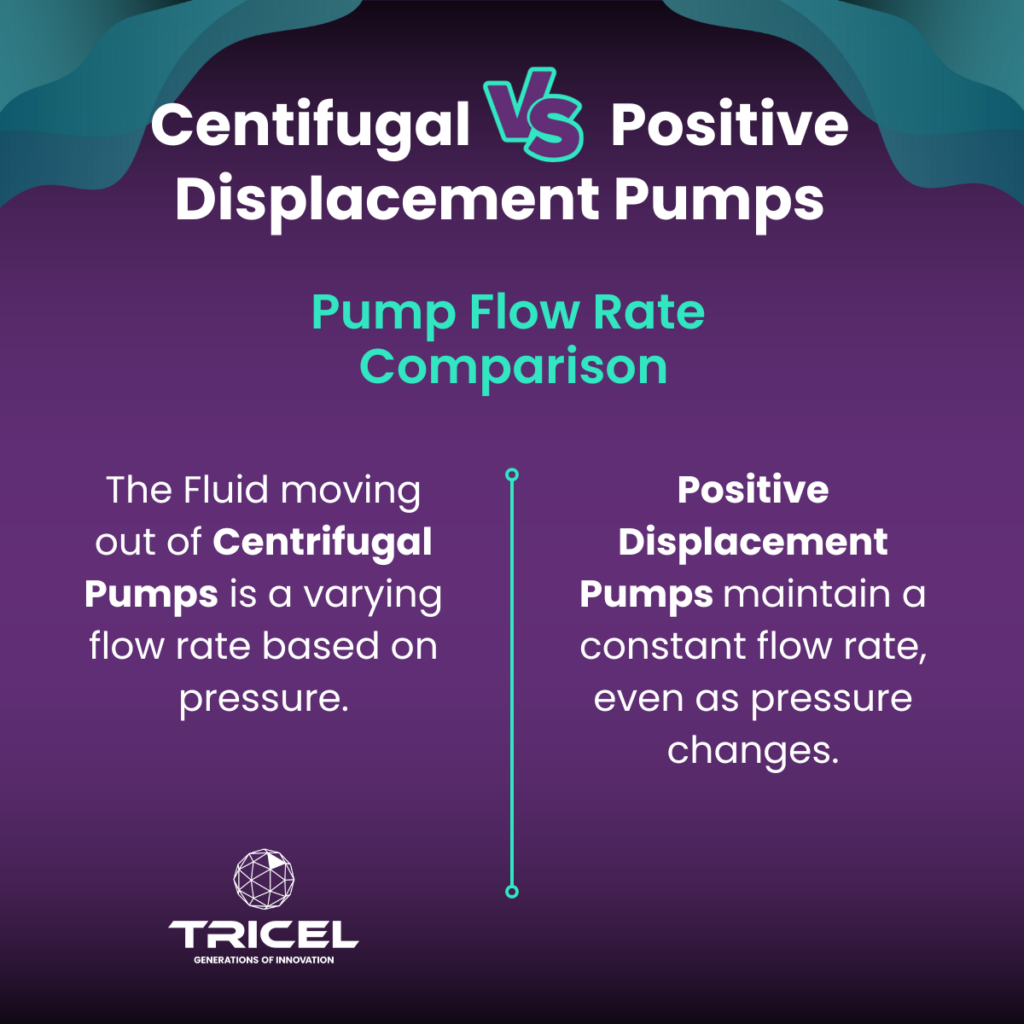

In the intricate world of fluid dynamics and pumping systems, the choice between centrifugal and positive displacement pumps is critical to operational efficiency and success. Each of these pumping solutions has distinct functionalities, offering a variety of advantages tailored to specific applications. From the relentless force of centrifugal pumps, harnessing the power of inertia to propel fluids, to the precision and consistency of positive displacement pumps, capturing and displacing liquid in measured increments—these two pumps are deployed in various industries.

To fully understand the differences between centrifugal and positive displacement pumps, you must know the fluid mechanics and system requirements. We will examine the different fluids they can handle and their suitable applications for each pump.

Fluid Transfer

A centrifugal pump and positive displacement pump each act by forcefully transferring water from an inlet to an outlet. The way they carry this transfer is different. A positive displacement pump draws fluid into a cavity and forces it out using a suction mechanism. Centrifugal pumps, on the other hand, have a rotating impeller that draws the liquid into the pump and forces it out at an increased velocity.

Types of Fluids Transferred

A distinct difference between centrifugal and positive displacement pumps is that a positive displacement pump is designed to handle viscous liquids, and the flow rate increases as the fluid gets thicker. They also handle sensitive liquids that change when pressure or force is applied. The frictional losses that centrifugal pumps have mean they typically cannot handle viscous fluids. The rotating impellers are a risk to the liquid.

Pump Performance

The flow rate in centrifugal and positive displacement pumps is a key difference. Whilst positive displacement pumps maintain a constant flow rate even through changes in pressure, centrifugal pumps have fluctuating flow rates that depend on the pressure. The flow rate through a positive displacement pump is directly proportional to its speed and number of cycles over a given time.

Suitable Applications

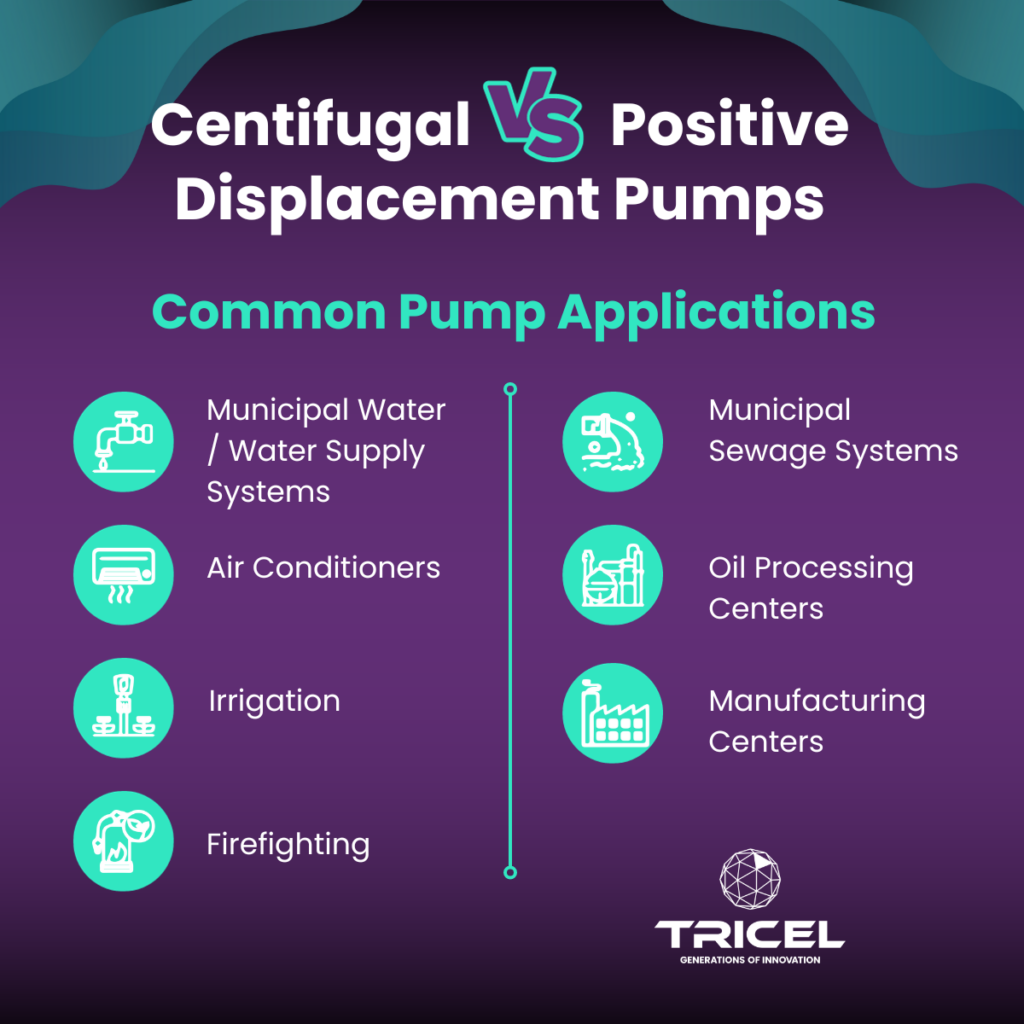

Centrifugal Pump Applications:

- Suitable for high-volume applications

- Municipal water systems

- Air conditioners and water circulators

- Irrigation

- Petrochemical and light fuel transfer stations

- Firefighting

- Cooling towers

- Boiler feeds

Positive Displacement Pump Applications:

- Ideal for high-pressure applications

- Municipal sewage systems

- Oil processing centres

- Manufacturing centres that produce or process thick pastes and other viscous materials

If you are in London, we offer a 24/7 emergency pump service call-out thanks to our network of first-class engineers. Call us on 02038 568 652 and speak to our expert team!

PACKAGED PUMPING SETS

Designed to deliver sufficient volume and water pressure

FIRE PUMPS

Full range of Fire Protection Pumps from small to packaged systems

PACKAGED PUMPING STATIONS

Pumping stations offer the ideal solution where gravity drainage is not possible

RECENT PROJECTS

Recent Projects Completed

Tricel is one of the largest UK pump distributors specialising in Commercial Building Services projects. We offer a wide range of products from circulator pumps to Wet Riser booster sets.

Our team includes experts which are happy to select and quote your equipment requirements, or attend site and size the equipment from scratch. We at Tricel pride ourselves on the highest possible levels of customer service, before, during, and after project completion.

We provide preventative maintenance contracts and also cater for specific repairs, including replacements seals, or complete overhauls.

150

Hotels

125

Schools

50

Hospitals

300

Apartment Blocks

305

Commercial Buildings

PUMP COMMISSIONING

Our skilled team of specialist engineers are ready to specify, supply, install, service and maintain pumps and their control systems

SERVICE & MAINTENANCE

We provide preventative maintenance contracts and also cater for specific repairs, including replacements seals or complete overhauls

SITE SURVEYS & ASSESSMENTS

Our technical team will visit your location and complete an entire site survey to ensure your project is accurately specified, and the most suitable system installed and maintained to the highest quality

CUSTOMER TECHNICAL SUPPORT

Through our 35 years of operation, we have accumulated a wealth of product knowledge and application experience that we use to support our customers