PUMPING SOLUTIONS

Buffer Vessels

OVERVIEW

In the world of water systems, specifically in domestic, commercial and industrial applications, buffer vessels might not be widely known. Still, they are important in maintaining stability, efficiency and safety in many industrial and commercial applications. The primary use of buffer vessels is to collect heat from multiple sources and store it for use later. This guide will discuss the different functions and benefits that buffer vessels serve and the different hot and chilled water buffer vessels available from Tricel.

If you have any questions, feel free to call us or use our quote form

To speak to one of our agents online, click here

The Key Functions of Buffer Vessels

Buffer vessels perform several essential functions, including:

- Pressure Stabilisation – they can absorb the excess pressure in a water system preventing any damage to the pipes and other parts and connections to the water system.

- Volume Compensation – temperature changes or the system demand can cause changes in the water volume, and the vessels help maintain the water volume.

- Preventing Water Hammer – a sudden surge in water pressure can cause damage to the water system. Buffer vessels are designed to absorb these shocks.

Here are the following requirements for buffer vessels:

- Horizontal buffer vessels would generally be installed indoors unless specifically designed for external use.

- The base must be level and strong enough to support the vessel.

- Adequate space must be left to provide access to the unit opening.

- Connections to the buffer vessel must be supported to avoid straining any connections.

- For ease of servicing and maintenance, isolation valves must be installed

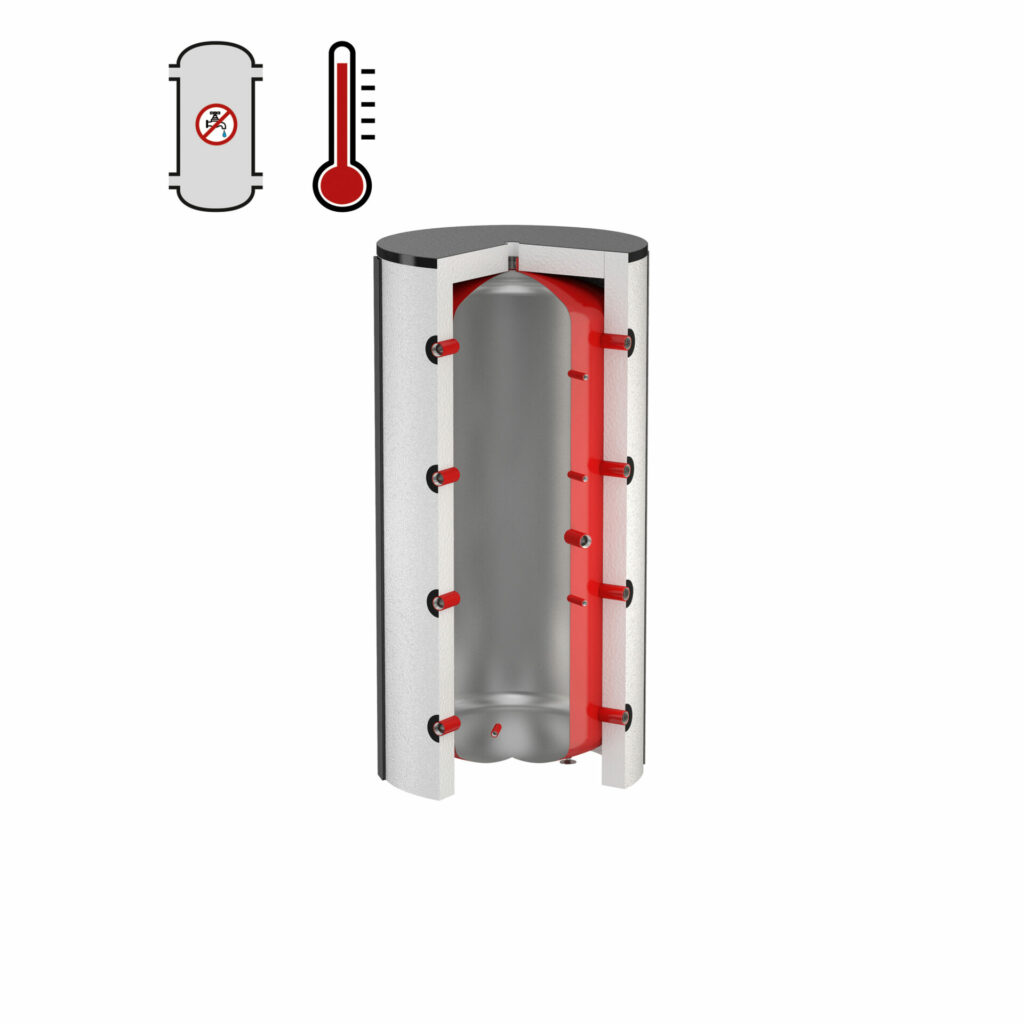

Chilled water buffer vessels

Buffer vessels used in chilled water applications would be located between the chillers and the distribution system. They prevent rapid cycling of the chillers. Chilled water buffer vessels are commonly used in HVAC systems to help chillers in air conditioning systems to avoid rapid cycling of the chillers and avoid temperature control issues. Low water volume systems may require additional buffer capacity installed as a solution.

Typically, vessels are manufactured in carbon or stainless steel. Stainless steel has the following benefits in buffer vessels:

- Extended lifespan vs alternative materials such as copper.

- Easy to install and maintain.

- Maximum storage capacity.

- Electric heating capabilities.

Tricel supplies buffer vessels from the top manufacturers in the industry, including Flamco. The FlexTherm PS-K 500 – 3000 chilled water buffer tank, including all flange connections for the water flow, is provided. They are durable, insulated vessels that are easy to install.

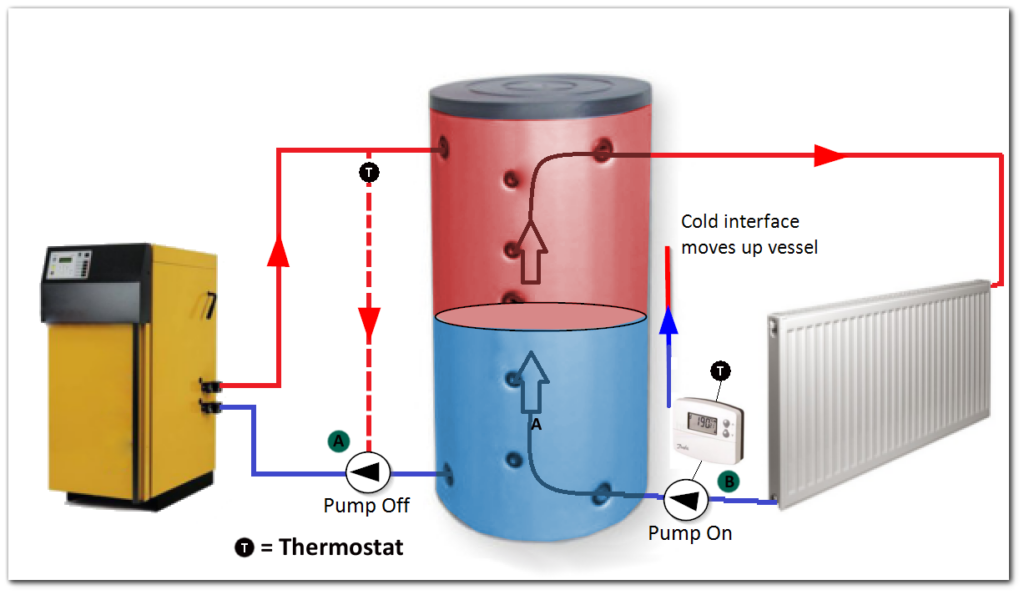

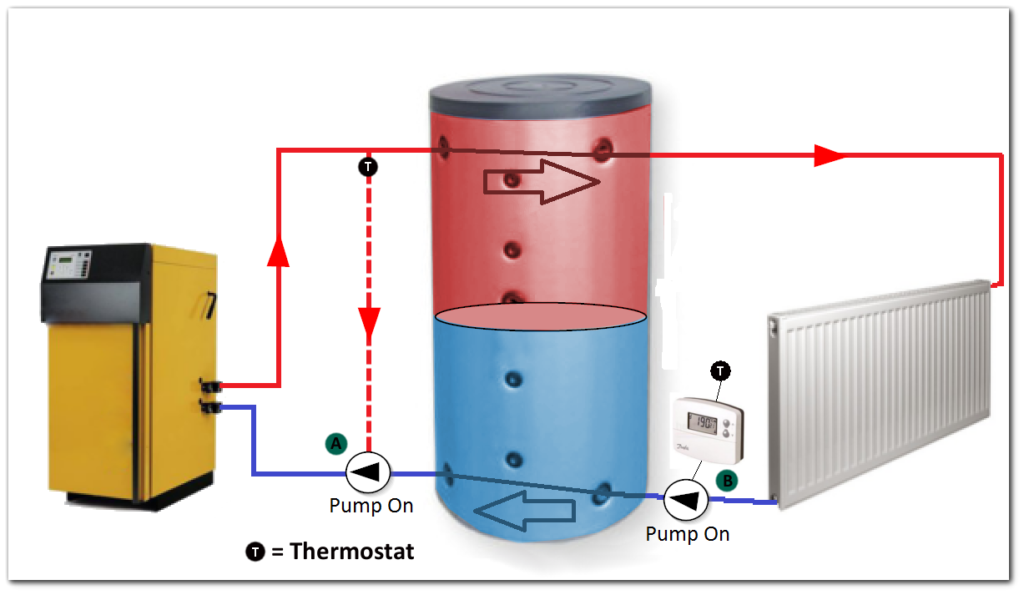

Hot Water buffer vessels

The units used for hot water are installed to provide more storage capacity when the demand for water during peak periods is more than the heat source can handle. For hot water applications, during periods of low demand, a buffer vessel heats the unit, and the heat is then released during periods of high demand.

An example to illustrate how a hot water buffer vessel works is as follows:

If a heat pump is in operation, its heat energy is kept in a buffer vessel and then drawn out when needed to supply heat to a radiator heating system.

We supply Flamco hot water buffer vessels used for closed heating installations. Flamco units are versatile and can be used in cooling installations as well, such as the FlexTherm PS 200 – 5000.

Key Difference between a hot water cylinder and a hot water buffer vessel:

- hot water cylinders store potable hot water

- buffer vessels add additional volume of hot water to the heating system

- a buffer vessel acts like a battery for heating systems

Buffer vessel sizing

The size of your buffer vessels depends on the application, heat output and demand of the water system, amongst many other factors. Contact our expert team, who will help you get an accurate size for your unit.

There are different ways to carry out sizing and calculating the size of your unit. The agreed size should be based on operation needs, installation and maintenance requirements, available space and weight of the vessel when it is full. A standard method used for buffer vessel sizing is using the litres per kW. An example for a customer to get the size of a unit would be 10 litres x 200kW = 2,000 litres.

Advantages of Using Buffer Vessels

The incorporation of buffer vessels in hot and cold water systems offers several advantages:

- Improved Efficiency

Buffer vessels enhance system efficiency by reducing pump cycling and minimising energy consumption.

- Extended Equipment Lifespan

By preventing pressure surges and water hammer effect, buffer vessels extend the lifespan of pumps, valves, and other water system components.

- Enhanced Safety

Buffer vessels contribute to safer operations by preventing overpressure incidents.

PACKAGED PUMPING SETS

Designed to deliver sufficient volume and water pressure

FIRE PUMPS

Full range of Fire Protection Pumps from small to packaged systems

PACKAGED PUMPING STATION

Pumping stations offer the ideal solution where gravity drainage is not possible

RECENT PROJECTS

Recent Projects Completed

Tricel is one of the largest UK pump distributors specialising in Commercial Building Services projects. We offer a wide range of products from circulator pumps to Wet Riser booster sets.

Our team includes experts which are happy to select and quote your equipment requirements, or attend site and size the equipment from scratch. We at Tricel pride ourselves on the highest possible levels of customer service, before, during, and after project completion.

We provide preventative maintenance contracts and also cater for specific repairs, including replacements seals, or complete overhauls.

150

Hotels

125

Schools

50

Hospitals

300

Apartment Blocks

305

Commercial Buildings

PUMP COMMISSIONING

Our skilled team of specialist engineers are ready to specify, supply, install, service and maintain pumps and their control systems

SERVICE & MAINTENANCE

We provide preventative maintenance contracts and also cater for specific repairs, including replacements seals or complete overhauls

SITE SURVEYS & ASSESSMENTS

Our technical team will visit your location and complete an entire site survey to ensure your project is accurately specified, and the most suitable system installed and maintained to the highest quality

CUSTOMER TECHNICAL SUPPORT

Through our 35 years of operation, we have accumulated a wealth of product knowledge and application experience that we use to support our customers