PUMPING SOLUTIONS

flamco pressurisation unit

Flamco pressurisation unit are essential components in modern heating and cooling systems, designed to maintain optimal pressure and ensure efficient operation. These compact, automated devices offer precise control and reliability for a wide range of applications, from residential to industrial settings.

If you have any questions, feel free to call us or use our quote form

To speak to one of our agents online, click here

Key features and benefits

AUTOMATIC PRESSURE MAINTENANCE: Flamco units automatically top up water in sealed heating and cooling systems, maintaining the required pressure levels.

VERSATILE APPLICATIONS: Suitable for domestic, commercial, and industrial sealed heating and cooling systems.

ADVANCED CONTROL SYSTEMS: Equipped with digital controllers featuring bright LED displays, microprocessor control, and user-friendly interfaces.

SAFETY FEATURES: Incorporate flood protection, pump protection, and alarm systems for enhanced safety and reliability.

COMMUNICATION CAPABILITIES: Many models support MODBUS RTU and BACnet protocols, allowing integration with building management systems.

PRODUCT RANGE

Flamco offers a diverse range of pressurisation units to meet various system requirements:

FLEXFILLER DIRECT G4 A compact, wall-mounted, pumpless unit ideal for smaller systems, operating silently and efficiently

FLEXFILLER MINI: Suitable for systems up to 2,600 liters, with a maximum operating pressure of 3.0 bar

FLEXFILLER MIDI: Designed for systems up to 50,000 liters, capable of pressurizing up to 5.0 bar

FLEXFILLER: For higher-demand applications, featuring an 18-liter reservoir and the ability to maintain pressures up to 13.0 ba

Installation and Maintenance

Proper installation is crucial for optimal performance:

Connect the unit and expansion vessel at the same point in the system for neutral pressure reading.

Ensure no non-return valves or pressure-reducing valves between the unit and the system.

Pre-charge the expansion vessel to match the unit’s cold fill pressure.

Regular maintenance, including annual service checks, ensures long-term reliability and efficiency.

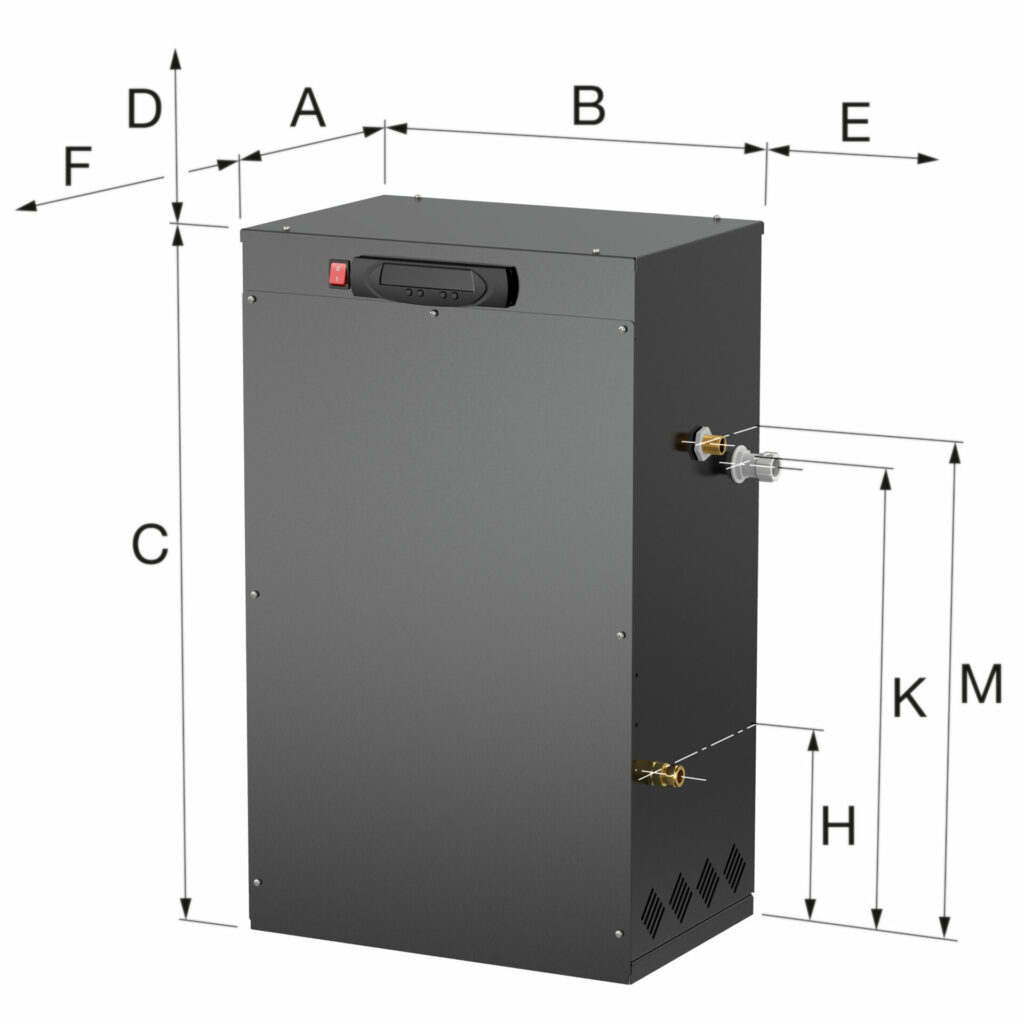

Technical Specifications

FAQ'S

Flamco pressurisation units offer several key benefits for heating and cooling systems:

Automatic pressure maintenance: These units automatically maintain optimal pressure levels in sealed heating and cooling systems.

Versatility: Suitable for a wide range of applications, including domestic, commercial, and industrial sealed systems.

Advanced control systems: Equipped with user-friendly digital controllers featuring microprocessor control and intuitive interfaces.

Enhanced safety: Incorporate features such as flood protection and alarm systems for reliable operation.

Communication capabilities: Many models support MODBUS RTU and BACnet protocols for integration with building management systems.

Improved efficiency: By maintaining consistent system pressure, these units help prevent cavitation and system damage, increasing overall system efficiency.

Reduced maintenance: The enclosed design helps prevent air contamination and oxidization, lowering maintenance costs over time.

Compact design: Units like the FlexFiller Direct G4 offer space-saving solutions for modern HVAC systems.

Silent operation: Some models, like the pumpless FlexFiller Direct G4, provide quiet performance.

Easy installation: Many Flamco units are designed for simple installation and commissioning, with plug-and-play functionality.

System health monitoring: Advanced units offer features like usage monitoring and system health checks for better management.

Compliance with regulations: Some models include water break tanks to comply with backflow prevention requirements.

Flamco offers a diverse range of pressurisation units to suit various applications and system requirements:

FlexFiller Direct G4: A compact, pumpless digital unit with a flow rate up to 14 l/min.

Flexfiller Mini: A low flow rate (<0.4 l/min) unit with a 2-liter break tank, ideal for residential or small commercial applications.

Flexfiller Midi/Digifiller: Wall-mounted units with flow rates up to 12 l/min and a 4-liter break tank.

Flexfiller Standard: A high flow rate (<18 l/min) unit with an 18-liter break tank.

Flexfiller Twin: Houses two high flow rate (<18 l/min) systems in a single enclosure, ideal for space-restricted areas.

PressDS: An additive top-up mixing pressurisation unit with a 4-liter break tank.

Flexfiller Plus: Available in various configurations, including Midifill and high-capacity models.

Packaged Sealed System Sets:

Basepak: Includes a Flexfiller unit, Flexcon expansion vessel, and connecting hose kit.

Presspak: Features a Presspak unit, Flexcon expansion vessel(s), and connecting hose kit.

PACKAGED PUMPING SETS

Designed to deliver sufficient volume and water pressure

FIRE PUMPS

Full range of Fire Protection Pumps from small to packaged systems

PACKAGED PUMPING STATION

Pumping stations offer the ideal solution where gravity drainage is not possible

RECENT PROJECTS

Recent Projects Completed

Tricel is one of the largest UK pump distributors specialising in Commercial Building Services projects. We offer a wide range of products from circulator pumps to Wet Riser booster sets.

Our team includes experts which are happy to select and quote your equipment requirements, or attend site and size the equipment from scratch. We at Tricel pride ourselves on the highest possible levels of customer service, before, during, and after project completion.

We provide preventative maintenance contracts and also cater for specific repairs, including replacements seals, or complete overhauls.

150

Hotels

125

Schools

50

Hospitals

300

Apartment Blocks

305

Commercial Buildings

PUMP COMMISSIONING

Our skilled team of specialist engineers are ready to specify, supply, install, service and maintain pumps and their control systems

SERVICE & MAINTENANCE

We provide preventative maintenance contracts and also cater for specific repairs, including replacements seals or complete overhauls

SITE SURVEYS & ASSESSMENTS

Our technical team will visit your location and complete an entire site survey to ensure your project is accurately specified, and the most suitable system installed and maintained to the highest quality

CUSTOMER TECHNICAL SUPPORT

Through our 35 years of operation, we have accumulated a wealth of product knowledge and application experience that we use to support our customers