PUMPING SOLUTIONS

Pumps For Water Removal

OVERVIEW

Water removal is critical to various industrial and commercial processes, requiring advanced and efficient solutions to ensure smooth operations. This guide delves into the technical aspects of pumps for water removal specifically designed for commercial and industrial settings.

If you have any questions, feel free to call us or use our quote form

To speak to one of our agents online, click here

The Importance of Specialised Pumps for Water Removal

In industrial and commercial sectors, effective water removal is vital for maintaining operational efficiency, preventing damage to equipment, and ensuring a safe working environment. Traditional methods may need to be revised, emphasising the need for specialised pumps designed to handle large volumes of water with precision and speed.

Types of Pumps for Water Removal

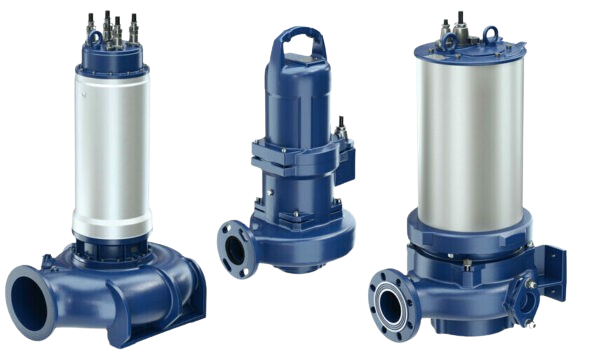

Submersible Pumps:

One of the most common choices for industrial water removal, submersible pumps are designed to operate while fully submerged. These pumps are highly efficient and capable of handling large volumes of water and solids. Their submersible nature makes them ideal for applications where space is restricted or where a quiet solution is preferred.

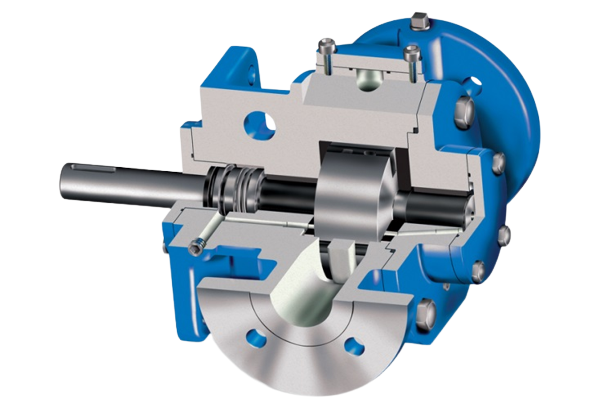

Centrifugal Pumps:

Centrifugal pumps are known for their versatility in handling various liquids, including water. These pumps use centrifugal force to move water, making them suitable for applications where a consistent and continuous flow is essential. They are often used in commercial settings due to their reliability and ease of maintenance.

Diaphragm Pumps:

Diaphragm pumps are excellent for handling water with high solids content. These positive displacement pumps use a flexible diaphragm to create a pumping action, allowing them to effectively handle viscous fluids and slurries. They are a preferred choice for industries with challenging water removal requirements.

Factors Influencing Pump Selection

Flow Rate

The required flow rate is crucial in selecting the right pump for water removal. Industrial and commercial applications often demand pumps with higher flow rates to ensure quick and efficient water evacuation.

Head Pressure

Understanding the head pressure, or the vertical distance the pump must move water, is essential. Different applications may require pumps with varying head pressure capabilities, and selecting the correct pump ensures optimal performance.

Solids Handling Capability

Industries dealing with wastewater or processes that produce solids need pumps with superior solids-handling capabilities. Diaphragm and submersible pumps, known for their ability to handle solids, are often preferred in such scenarios.

Durability and Material Selection

Pumps are subject to harsh conditions in commercial and industrial environments. Opting for pumps made from durable materials ensures longevity and minimises the risk of breakdowns. Stainless steel and corrosion-resistant materials are often preferred for industrial water removal applications.

Integration of Smart Technologies in Water Removal Pumps

Variable Frequency Drives (VFDs)

Modern water removal pumps often feature Variable Frequency Drives, allowing for adjustable speed and flow rates. These variable frequency drives contribute to energy efficiency and enable precise control over the water removal process. Industries can benefit from optimising pump performance based on specific operational needs.

Installation and Maintenance Considerations

Proper Installation

Efficient water removal relies heavily on proper pump installation. Engaging qualified technicians to install pumps ensures they are integrated seamlessly into the existing infrastructure. Correct installation not only maximises performance but also extends the pump’s lifespan.

Regular Maintenance Protocols

To uphold the reliability of water removal pumps, adhering to a robust maintenance schedule is imperative. Maintenance includes routine inspections, lubrication of moving parts, and proactive replacement of worn components. Regular maintenance prevents unexpected failures, reducing the risk of costly downtime

If you are in the London area, we offer a 24/7 emergency pump service call out thanks to our first-class network of engineers based in London.

As industrial and commercial landscapes continue to evolve, so do the technologies associated with pumps for water removal. The integration of smart technologies, emphasis on energy efficiency, and advancements in materials will play pivotal roles in shaping the future of water removal solutions.

For commercial and industrial customers, staying abreast of these developments is not just a matter of convenience but a strategic imperative. The right water removal pump and a commitment to proper installation and maintenance practices ensure a seamless workflow and safeguards against potential disruptions.

In conclusion, the landscape of pumps for water removal is expanding, offering innovative solutions to meet the different needs of industrial and commercial applications. By embracing these advancements and leveraging technical expertise, businesses can achieve unparalleled efficiency in managing water removal challenges, contributing to sustainable and resilient operations.

For those navigating the complex world of water removal pumps, consulting with industry experts and keeping pace with technological advancements is critical to making informed decisions and ensuring long-term success in water management.

Investing in advanced water removal solutions safeguards equipment and processes and contributes to a safer and more efficient working environment. By staying informed about the latest advancements in pump technology, industries can stay ahead in managing water removal challenges effectively.

PACKAGED PUMPING SETS

Designed to deliver sufficient volume and water pressure

FIRE PUMPS

Full range of Fire Protection Pumps from small to packaged systems

PACKAGED PUMPING STATIONS

Pumping stations offer the ideal solution where gravity drainage is not possible

RECENT PROJECTS

Recent Projects Completed

Tricel is one of the largest UK pump distributors specialising in Commercial Building Services projects. We offer a wide range of products from circulator pumps to Wet Riser booster sets.

Our team includes experts which are happy to select and quote your equipment requirements, or attend site and size the equipment from scratch. We at Tricel pride ourselves on the highest possible levels of customer service, before, during, and after project completion.

We provide preventative maintenance contracts and also cater for specific repairs, including replacements seals, or complete overhauls.

150

Hotels

125

Schools

50

Hospitals

300

Apartment Blocks

305

Commercial Buildings

PUMP COMMISSIONING

Our skilled team of specialist engineers are ready to specify, supply, install, service and maintain pumps and their control systems

SERVICE & MAINTENANCE

We provide preventative maintenance contracts and also cater for specific repairs, including replacements seals or complete overhauls

SITE SURVEYS & ASSESSMENTS

Our technical team will visit your location and complete an entire site survey to ensure your project is accurately specified, and the most suitable system installed and maintained to the highest quality

CUSTOMER TECHNICAL SUPPORT

Through our 35 years of operation, we have accumulated a wealth of product knowledge and application experience that we use to support our customers