PUMPING SOLUTIONS

Sewage Pumping Station

OVERVIEW

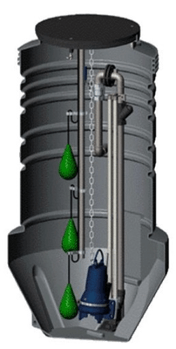

A sewage pumping station is crucial in managing wastewater efficiently across various settings, from residential neighborhoods to bustling commercial and industrial zones. The pumping station moves sewage from lower to higher elevations. Each sewage pumping station pumps raw sewage and wastewater into pipes, transporting the waste to a treatment plant or other disposal site.

If you have any questions, feel free to call us or use our quote form

To speak to one of our agents online, click here

What is a sewage pumping station?

Sewage pumping stations are facilities designed to transport wastewater from lower to higher elevations. They are equipped with pumps that facilitate the smooth flow of sewage, preventing backups and ensuring proper disposal.

Types of Sewage Pumping Stations

- Dry well sewage pumping station

Dry-well sewage pumping stations represent a cost-effective and straightforward solution within sewage pumping infrastructure. These stations employ a singular pump housed in a chamber constructed from concrete or steel. It is essential to note that the applicability of dry-well stations depends on the soil’s capacity to support the pump’s weight adequately.

- Wet-well sewage pumping station

wet-well sewage pumping stations, although more costly, present a heightened level of adaptability as they can be deployed in diverse soil conditions. Comprising a substantial underground tank for wastewater storage, these stations afford greater flexibility in pump processing times. Additionally, the continuous circulation of wastewater in wet-well stations reduces the likelihood of clogging.

- Pre-case sewage pumping station

Pre-cast sewage pumping stations emerge as a premium choice for those prioritising durability and reliability despite their higher associated costs. Crafted from robust materials such as concrete or fibreglass, these stations are engineered to endure challenging weather conditions, ensuring prolonged operational effectiveness.

Components of a Sewage Pumping Station

- Pumps: Various types, including centrifugal and submersible, are used based on specific requirements.

- Wet Wells: Underground chambers that collect and temporarily store sewage before it is pumped to the treatment facility.

- Control Panels: Advanced systems that regulate pump operations, monitor fluid levels, and provide alarms for potential issues.

Different applications for sewage pumping stations

Residential Applications

- Single-family Homes:

- Compact, submersible pumps ideal for individual residences.

- Gravity-driven systems for areas with minimal elevation changes.

- Intelligent control systems for energy efficiency and reduced maintenance.

- Multi-unit Dwellings:

- Customisable solutions for apartment buildings and complexes.

- Variable speed pumps for efficient handling of fluctuating wastewater volumes.

- Remote monitoring capabilities for prompt issue detection.

Commercial Applications

- Retail and Office Spaces:

- Robust pumps are designed for handling commercial wastewater with varying contaminants.

- Duplex pump systems for redundancy and reliability.

- Integration with building management systems for seamless operation.

- Hotels and Hospitality:

- High-capacity pumps are suitable for large volumes of wastewater.

- Grease traps and screens to prevent clogs from kitchen and laundry discharges.

- Regular maintenance schedules to ensure uninterrupted service.

Industrial Applications

- Manufacturing Facilities:

- Heavy-duty pumps capable of handling industrial effluents.

- Chemical-resistant materials for compatibility with diverse waste streams.

- Emergency backup systems to prevent production downtime.

- Processing Plants:

- Custom-engineered solutions for specialised industries like food processing and pharmaceuticals.

- ATEX-certified pumps for hazardous environments.

- Comprehensive monitoring and control systems to meet regulatory requirements.

Challenges in Industrial Projects:

- Corrosion Control: Sewage pumping stations face constant exposure to corrosive elements. Advanced corrosion-resistant coatings, materials, and cathodic protection systems are employed to mitigate the impact of corrosive gases and substances, extending the life of station infrastructure.

- Odour Control: Hydrogen sulfide gas, a byproduct of sewage decomposition, poses a significant challenge in pumping station design. Odour control systems, including chemical scrubbers and air treatment technologies, are integrated to ensure a safe and comfortable working environment for operators and nearby residents

Maintenance & Best Practices

- Regular Inspection:

- Scheduled inspections of pumps, valves, and control systems, including the float switch

- Proactive identification and replacement of worn-out components.

- Checking for any irregularities with the power supply.

- Inspecting the suction and discharge lines

- Preventive Maintenance:

- Regular cleaning of wet wells to prevent buildup and odours.

- Lubrication of moving parts for optimal performance.

- Cleaning the pump and filters

If your sewage pumping station requires repairs, it is crucial to contact our qualified technical teams as soon as possible. We have a network of specialist engineers in London, allowing us to offer our customers 24/7 emergency service call-outs. We offer our customers throughout the UK preventative maintenance contracts suited to their specific requirements.

Investing in the right sewage pumping station is crucial for maintaining public health and environmental sustainability. From residential areas to industrial complexes, understanding the unique demands of each setting ensures the proper selection and maintenance of sewage pumping solutions. Communities can guarantee efficient and reliable wastewater management for years by implementing advanced technologies and adhering to best practices.

PACKAGED PUMPING SETS

Designed to deliver sufficient volume and water pressure

FIRE PUMPS

Full range of Fire Protection Pumps from small to packaged systems

PACKAGED PUMPING STATIONS

Pumping stations offer the ideal solution where gravity drainage is not possible

RECENT PROJECTS

Recent Projects Completed

Tricel is one of the largest UK pump distributors specialising in Commercial Building Services projects. We offer a wide range of products from circulator pumps to Wet Riser booster sets.

Our team includes experts which are happy to select and quote your equipment requirements, or attend site and size the equipment from scratch. We at Tricel pride ourselves on the highest possible levels of customer service, before, during, and after project completion.

We provide preventative maintenance contracts and also cater for specific repairs, including replacements seals, or complete overhauls.

150

Hotels

125

Schools

50

Hospitals

300

Apartment Blocks

305

Commercial Buildings

PUMP COMMISSIONING

Our skilled team of specialist engineers are ready to specify, supply, install, service and maintain pumps and their control systems

SERVICE & MAINTENANCE

We provide preventative maintenance contracts and also cater for specific repairs, including replacements seals or complete overhauls

SITE SURVEYS & ASSESSMENTS

Our technical team will visit your location and complete an entire site survey to ensure your project is accurately specified, and the most suitable system installed and maintained to the highest quality

CUSTOMER TECHNICAL SUPPORT

Through our 35 years of operation, we have accumulated a wealth of product knowledge and application experience that we use to support our customers