PUMPING SOLUTIONS

Basement Pumping

OVERVIEW

In commercial and industrial spaces, efficient management of below-grade environments is essential to maintain a clean and structurally secure basement. One crucial aspect that demands attention is basement pumping.

If you have any questions, feel free to call us or use our quote form

To speak to one of our agents online, click here

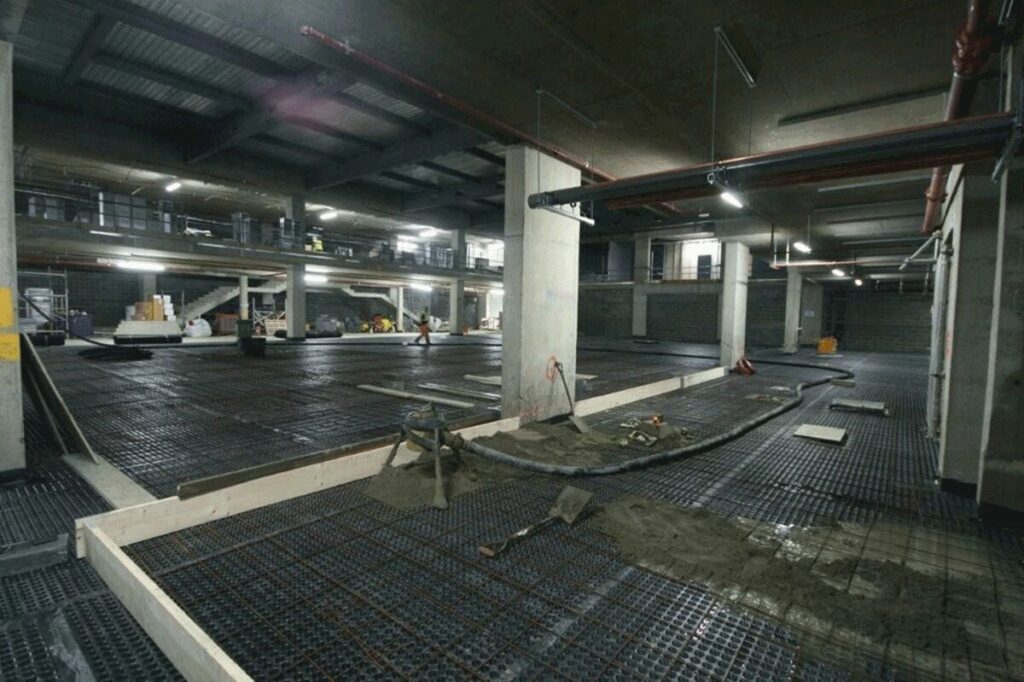

Basement Pumping for Commercial and Industrial Applications

Commercial and industrial facilities often feature expansive basements that house critical infrastructure worth thousands of pounds. From storage areas to utility spaces, the proper functioning of these lower levels is integral to the overall operational efficiency of the business. Basement pumping is, therefore, a crucial solution, ensuring the controlled removal of excess water and preventing potential damage to the basement floor and structure.

Types of Basement Pumping Systems

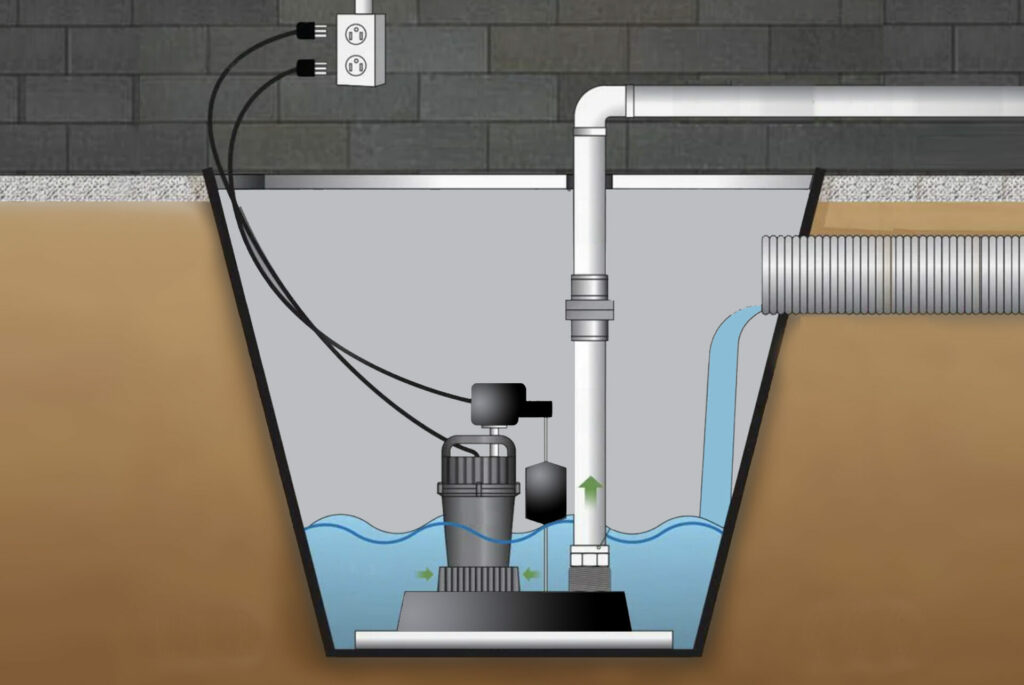

Sump Pump Systems

Sump pump systems stand as the frontline defence against basement flooding. These systems comprise a sump pit, pump, and discharge pipe. The way sump pumps operate is straightforward: when the water level in the sump pit reaches a certain level, a float switch activates the pump. The pump then removes water and discharges it away from your basement.

Sump pumps can be single or double pumping systems, with double systems typically costing more but being designed to remove more water. Expertly installed, they efficiently collect and expel water, preventing it from seeping into the foundation and safeguarding the structural integrity of the commercial or industrial space.

Submersible Pump Systems

If water in the basement needs to be pumped away, submersible pumps are the ideal solution. These pumps operate while submerged in water and are suitable for continuous and high-capacity water removal. Their robust build and powerful performance make them indispensable in demanding industrial environments.

Basement Pump Design

Variable Speed Control

Modern basement pumping solutions for commercial and industrial clients often incorporate variable speed control. This feature allows for precise pump speed adjustment based on real-time water levels, optimising energy consumption and ensuring a tailored approach to water removal.

Advanced Sensor Technologies

The integration of cutting-edge sensor technologies elevates basement pumping to a new level. Smart sensors can detect real-time water levels, pump performance, and potential malfunctions, enabling proactive maintenance and minimising the risk of unexpected system failures.

Basement Pumping Within Industrial Settings

Customised System Integration

A one-size-fits-all approach to basement pumping is not the right solution for large-scale industrial facilities. Tailored solutions involve a comprehensive assessment of the space’s unique requirements, leading to the integration of specialised pumping systems that ensure optimal performance and longevity and meet your scale of operations.

Redundancy Planning

In critical industrial settings, the cost of downtime due to a basement flooding incident can be astronomical. Advanced basement pumping solutions include redundancy planning, ensuring that backup systems seamlessly take over in case of primary pump failure, and guaranteeing uninterrupted operations.

How to pump water out of a flooded basement

- Only enter a flooded basement if you know the electricity is switched off.

- Take pictures before starting any work (for insurance purposes)

- When the water is no longer covering the ground around the perimeter of your building, you can start pumping the water from your basement.

- Do not use gasoline-powered pumps or generators indoors as they produce deadly carbon monoxide exhaust fumes.

- Lower the water level by 2 to 3 feet, make a clear mark at the achieved level, and let it settle overnight.

- Assess the water level the following day. If it has risen and covered the marked point, deferring the basement drainage is advisable.

- Allow an additional 24-hour period to elapse. Subsequently, reduce the water level by 2 to 3 feet once again and examine it the next day.

- Continue this process until the water ceases to ascend. Upon reaching this point, decrease the water level by an additional 2 to 3 feet and observe overnight. Repeat these steps iteratively until the basement is entirely devoid of water.

Why Basement Pumps Fail?

Over time, the accumulation of dirt and debris can obstruct the optimal functioning of a basement pump. In the event of a power outage, if the primary pump loses power, it becomes non-operational, underscoring the importance of integrating a battery backup pump into your basement waterproofing system.

Should the float switch become overworked, it can lead to a decline in the efficiency of the basement pump system, potentially resulting in a complete breakdown. Regular inspection and cleaning are vital to ensure the continued effectiveness of the basement system. The increasing vulnerability of the UK to flooding adds another layer of concern, as flooding can result in property damage and substantial repair costs.

Employing a sump pump system with a cavity drain membrane proves advantageous in minimising the risk of basement flooding. Sump chambers are designed with easily removable lids, providing convenient access to the pumps, while the perimeter drainage incorporates inspection ports for system flushing and removing mud and silt.

Basement pumping servicing

How basement pumps are serviced and when to carry out periodic maintenance are frequently asked questions from customers, and it depends on the vulnerabilities your property may encounter, such as the likelihood of flooding and the frequency of sump pump system utilisation. Typically, pump maintenance is sufficient once annually, but we advocate for a biannual schedule to ensure optimal functionality, particularly after the recent installation of your basement sump pump.

The British Standards also endorse a six-month servicing interval for sump pumps. This recommendation stems from the inherent risk of basement flooding, a significant concern impacting properties in the UK, as previously detailed.

Basement pumping stands out as a pivotal element in fortifying investments and ensuring uninterrupted operations within the intricate framework of commercial and industrial environments. The skilled management of below-grade water requires a keen understanding of basement pumping solutions.

Packaged Pumping Sets

Designed to deliver sufficient volume and water pressure

Fire Pumps

Full range of Fire Protection Pumps from small to packaged systems

Packaged Pumping Stations

Pumping stations offer the ideal solution where gravity drainage is not possible

RECENT PROJECTS

Recent Projects Completed

Tricel is one of the largest UK pump distributors specialising in Commercial Building Services projects. We offer a wide range of products from circulator pumps to Wet Riser booster sets.

Our team includes experts which are happy to select and quote your equipment requirements, or attend site and size the equipment from scratch. We at Tricel pride ourselves on the highest possible levels of customer service, before, during, and after project completion.

We provide preventative maintenance contracts and also cater for specific repairs, including replacements seals, or complete overhauls.

150

Hotels

125

Schools

50

Hospitals

300

Apartment Blocks

305

Commercial Buildings

PUMP COMMISSIONING

Our skilled team of specialist engineers are ready to specify, supply, install, service and maintain pumps and their control systems

SERVICE & MAINTENANCE

We provide preventative maintenance contracts and also cater for specific repairs, including replacements seals or complete overhauls

SITE SURVEYS & ASSESSMENTS

Our technical team will visit your location and complete an entire site survey to ensure your project is accurately specified, and the most suitable system installed and maintained to the highest quality

CUSTOMER TECHNICAL SUPPORT

Through our 35 years of operation, we have accumulated a wealth of product knowledge and application experience that we use to support our customers