PUMPING SOLUTIONS

Industrial Pumps

OVERVIEW

Industrial pumps are heavy-duty water pumps commonly used to move different materials and matter, including wastewater, chemicals, gas, oil and other substances. An industrial pump moves the liquid from one location to another and accelerates it when it needs to move at high flow rates. Any water pump designed to move materials for industrial use is considered an industrial pump.

If you have any questions, feel free to call us or use our quote form

To speak to one of our agents online, click here

What Are Industrial Pumps Used For?

Industrial pumps are needed primarily for moving materials. They make it far easier for liquids, gases and materials to be manipulated and moved. For example, water pumps fill a storage tank quickly and efficiently. This is just a basic example of using an industrial pump, but they are invaluable in industries handling dangerous and hazardous materials.

An industrial pump is comprised of an inlet tube, a motor and impeller, and an outlet. However, how they function will differ depending on the type of pump you are using. Many other industrial pumps are named purely on what functions they perform. These include concrete pumps, slurry pumps, paint pumps, grinder pumps, and many others.

Pumps you find in your household or for medical and scientific use are not classed as industrial pumps, even though they might possess the same basic pumping mechanisms used on a much larger scale in an industrial pump.

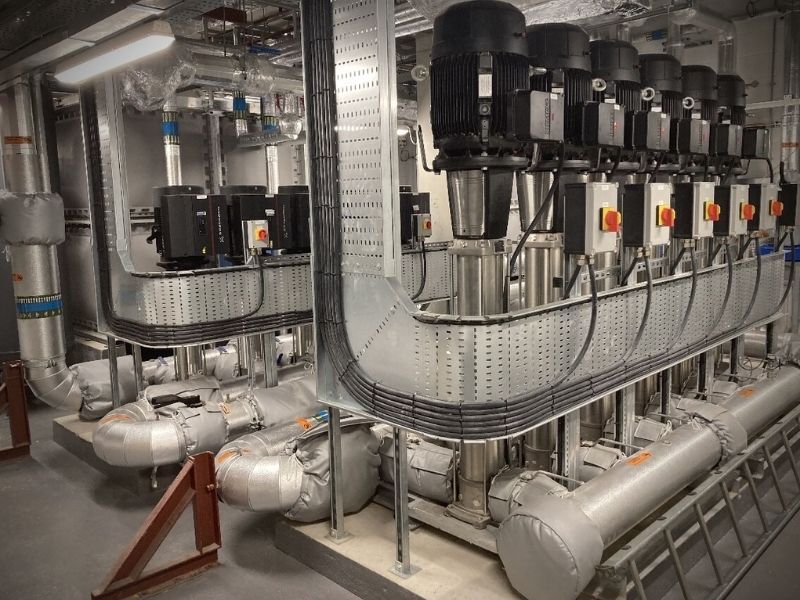

Our Expertise Supplying Industrial Pumps

We have 35 years of experience in the industry as an authorised pump distributor within the UK for major brands such as Grundfos, Lowara, Xylem, Wilo, DAB and many others. Our expertise is mainly focused on commercial and industrial building services.

We supply industrial water pumps and offer installation and commissioning on pumps to different industries. From commercial water booster pumps, pressurisation units and expansion vessels, heating and chiller circulator pumps, and variable speed pumps to wastewater pumping stations.

Tricel offers complete service packages, including 24/7 emergency call-out service in London and preventative maintenance contracts.

Types Of Industrial Pumps

You will need an industrial pump if you run a business that requires fluid movement, processing, or management. Typically, businesses will struggle choosing the right type of pump for the job because there are many options. There are two types of industrial water pumps: positive displacement pumps and dynamic pumps.

Positive Displacement Pump

Positive displacement pumps use the reciprocating motion of plungers, pistons, or diaphragms to move fluids through the pump at steady rates with high degrees of pressure. There’s a vast range of pump types like these, such as screw pumps, gear pumps, piston pumps, diaphragm pumps, peristaltic pumps, progressive cavity pumps, and many others. Instead of a smooth transfer of liquid, you generally get a pulsing discharge with this type of pump because fluid is trapped and expelled in a fixed volume. A positive displacement pump has a more complex design than dynamic pumps and is designed to handle fluctuations in flow and pressure.

Dynamic Pump

Alternatively, there are dynamic pumps, most commonly centrifugal pumps. Dynamic pumps use centrifugal force to create velocity in the liquid that the pump is handling. That velocity gets converted to pressure, which can be regulated to push fluid through the pump. Dynamic pumps contain an impeller, which creates a vacuum that drives fluid inside the pump’s housing. These are the most common types of industrial pumps because they have the fewest moving parts and can operate continuously.

Types of Dynamic Pumps

CENTRIFUGAL PUMPS

Many industries will make use of centrifugal pumps. The pumps transfer liquids using their motor-driven rotors known as impellers. The rotating impellers accelerate the fluid and increase its pressure.

Fluid enters the rotating impeller along the pump’s axis and is expelled by centrifugal force toward the pump’s outlet. This type of pump can handle liquids that contain suspended solids. There are also different types designed to meet various industrial needs.

N.B centrifugal pumps create flow, not pressure, making them the ideal solution for applications that require high flow rates for low-viscosity liquids.

SUBMERSIBLE PUMPS

Industrial businesses mainly use submersible pumps to move sewage and stormwater, but they can also be used in many other applications, including drainage, general industrial pumping and slurry pumping.

Submersible pumps work under extreme conditions and are ideal for shifting waste, chemicals, grey water, and food.

FIRE PUMPS

Fire pumps are designed to support fire suppression systems or sprinkler tanks. The pumps transfer water at high pressure and high force, so the firefighting industry primarily uses them. Fire pumps may be installed in industrial settings or at the street level, connected directly to a municipal water system.

Which Industries Use Industrial Pumps?

Industrial pumps are used throughout most industries in some way or another. Any large-scale business requiring moving materials and liquids from one place to another will need an industrial pump. Industrial pumps are necessary whether it’s oil and gas, renewable energy, marine, manufacturing or food and beverage businesses.

Industrial pumps are a valuable investment for businesses, ensuring that materials are moved safely. They are often used for transferring hazardous or waste materials, so industrial pumps keep workplaces safe for employees. Industrial pumps also ensure that operations are not disrupted, as they can move materials quickly and effectively.

Key Industries:

- Oil & Gas

- Mining

- Water & Wastewater Treatment

- Power Generation

- Chemical & Petrochemical

For more information on industrial pumps or advice and guidance on the best industrial pump for your application, contact our expert sales team.

PACKAGED PUMPING SETS

Designed to deliver sufficient volume and water pressure

FIRE PUMPS

Full range of Fire Protection Pumps from small to packaged systems

PACKAGED PUMPING STATIONS

Pumping stations offer the ideal solution where gravity drainage is not possible

RECENT PROJECTS

Recent Projects Completed

Tricel is one of the largest UK pump distributors specialising in Commercial Building Services projects. We offer a wide range of products from circulator pumps to Wet Riser booster sets.

Our team includes experts which are happy to select and quote your equipment requirements, or attend site and size the equipment from scratch. We at Tricel pride ourselves on the highest possible levels of customer service, before, during, and after project completion.

We provide preventative maintenance contracts and also cater for specific repairs, including replacements seals, or complete overhauls.

150

Hotels

125

Schools

50

Hospitals

300

Apartment Blocks

305

Commercial Buildings

PUMP COMMISSIONING

Our skilled team of specialist engineers are ready to specify, supply, install, service and maintain pumps and their control systems

SERVICE & MAINTENANCE

We provide preventative maintenance contracts and also cater for specific repairs, including replacements seals or complete overhauls

SITE SURVEYS & ASSESSMENTS

Our technical team will visit your location and complete an entire site survey to ensure your project is accurately specified, and the most suitable system installed and maintained to the highest quality

CUSTOMER TECHNICAL SUPPORT

Through our 35 years of operation, we have accumulated a wealth of product knowledge and application experience that we use to support our customers